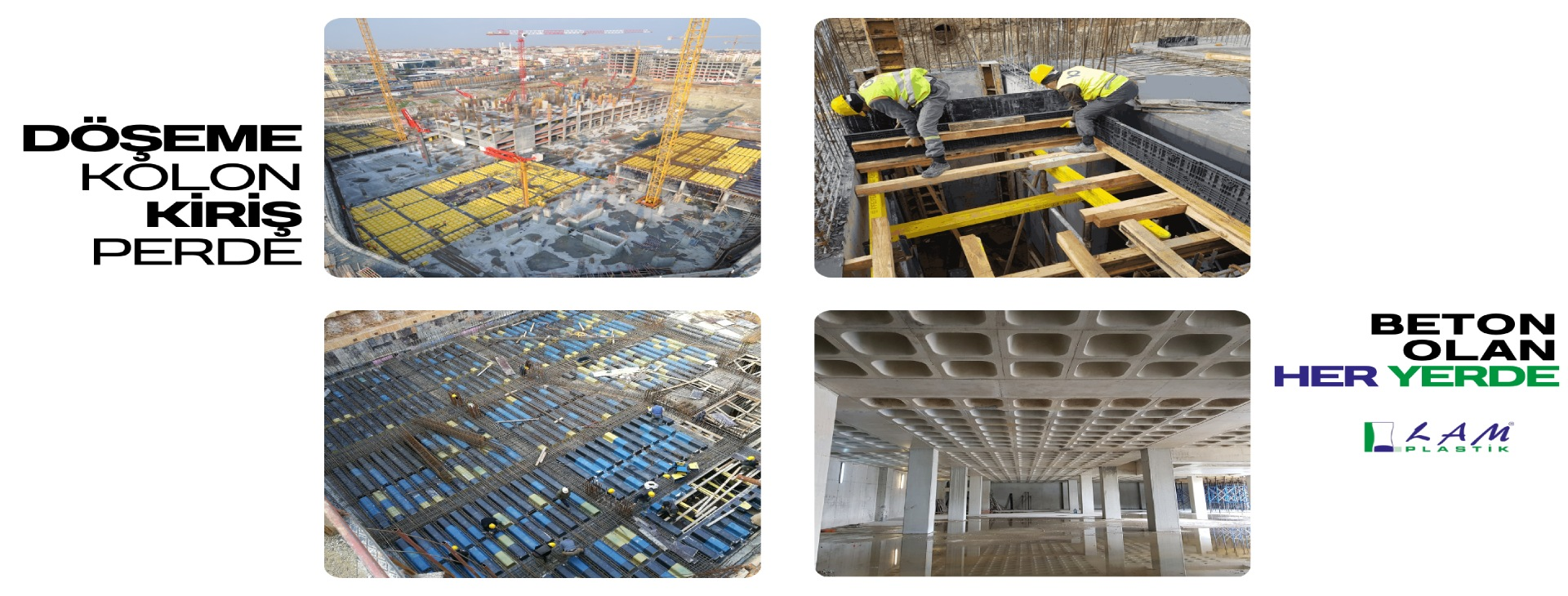

Ürünlerimiz

LAM PLASTİK

Markalarımız

Tecrübe

Kurum olarak sahip olduğumuz tecrübe ile çalışanlarımızın tecrübelerini birleştiriz.

Planlama

Bir işe başlamadan önce yaptığımız planlama sayesinde, kusursuz hizmet veririz.

Profesyonel Ekip

Çalışanlarımız işinde uzman ve yaptıkları işin önemini bilen kişilerden oluşur.